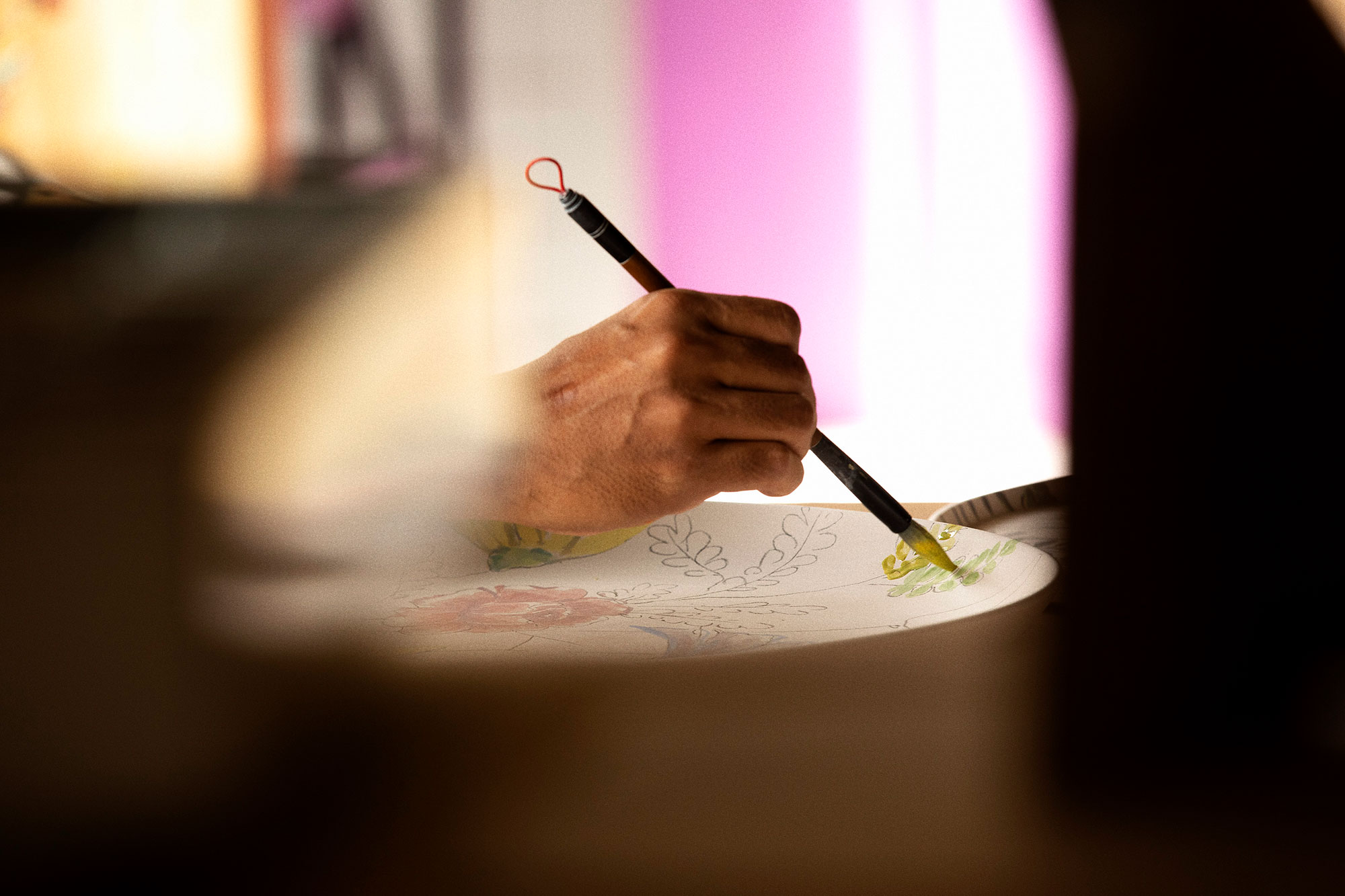

Vartula is more than a sustainable collection, it’s a reflection of how thoughtful design can respond to pressing environmental challenges. Created by Sara Howard, a designer deeply engaged in circular practices, this fifteen-piece tableware line builds on Kevala’s circular ceramics legacy by incorporating reclaimed glass waste from Bali’s rivers, collected in partnership with Sungai Watch. Behind the collection lies a story of experimentation, collaboration, and purpose. In this interview, we speak with Sara to understand how waste materials are transformed into durable, elegant tableware, and how local partnerships are shaping the future of sustainable production.

Q: In what ways does the Vartula collection represent an evolution from Kevala’s previous circular ceramics initiatives?

I launched the Circular Ceramics collection with Kevala two years ago, inspired by a desire to create low-impact tableware on a larger scale. What began as a research venture quickly became Kevala’s best-selling collection, finding its way into hotels, restaurants, homes, and exhibitions around the world.

Encouraged by the response, I continued exploring how local waste materials in Bali could replace virgin resources. By building relationships with local industries, organisations, and individuals, I found new ways to extend the lifecycle of more overlooked resources.

Vartula emerged from this process. A fifteen-piece tableware collection created for the hospitality industry, offering an alternative design rooted in conscious material use and thoughtful design.

Q: The glazes in Vartula incorporate glass waste sourced from Bali. Could you share insight into how this reclaimed material found its way into Kevala’s production?

I’ve always believed that meaningful partnerships can emerge from shared values, and the relationship with Sungai Watch is one I’m especially proud of. When I arrived in Indonesia and began to understand how waste is managed here, I quickly learned that Bali’s 400+ rivers often serve as informal waste disposal channels for many communities.

Through Sungai Watch’s work, installing barriers and mobilising river warriors to retrieve and sort waste, the glass they retrieved quickly caught my eye. With no recycling facilities in Bali and transportation to Java limited by the weight of glass, the material began to accumulate, with nowhere to go.

This challenge presented an opportunity. I began exploring how this recovered glass might replace virgin materials typically mined and imported for ceramic production at Kevala. From this inquiry, two new glazes were developed, each able to stand alone or be layered to form a textured surface.

Q: What is the significance behind the name Vartula, and how does it reflect the ethos of the collection?

Vartula is the Sanskrit word for circular, embodying regenerative design where the discarded becomes the essential. Kevala, meaning whole and complete, also holds deep significance. Together, these words capture how I approach ceramic production, with a holistic perspective that considers a material’s lifecycle long before it reaches our factory floor.

In today’s complex supply chains, tracing the origins and endpoints of materials can be challenging. That lack of transparency often hides the social and ecological costs of extraction. My work focuses on rebuilding those supply chains, locally, so we can reduce harm, remain accountable, and design with intention. Keeping it local, to keep it conscious.

Q: Looking ahead, how do you envision the next chapter of sustainability at Kevala? What innovations or directions are you exploring to advance sustainable design further?

Sustaining sustainability requires more than a single innovation; it asks for long-term commitment, continuous reflection, and the willingness to evolve. It’s not as simple as introducing a new waste material or developing a glaze. True impact is found in the systems we build and the behaviours we shift over time.

At Kevala, we’ve now established a dedicated sustainability team working full-time to embed sustainable practices across the company. From training staff on proper waste sorting to refining in-house processes for greater efficiency, we’re learning how to integrate accountability into our daily operations. A new data logging system enables us to track our waste streams each month, helping us identify where we can make the most meaningful changes.

Since joining Kevala, I’ve seen sustainability move from an idea into a shared responsibility, woven into our departments, our supply chain, and our client relationships. It’s taken time to get here, but with clarity in our direction and systems in place, we’re now ready to act with intention.

Q: What role do local partnerships and community engagement play in the development of Vartula and Kevala’s broader sustainability efforts?

So many industries still operate in silos, with little dialogue between manufacturers. As a result, valuable by-products are often discarded without consideration for how they might live on. For me, building local partnerships has been essential, not just for exchanging materials, but for opening up honest conversations around process, waste, and potential.

Approximately 95% of materials used in manufacturing never make it into the final product. In an era where natural resources are increasingly scarce and extraction comes at a growing environmental cost, this statistic can no longer be ignored. We are entering a new waste age, one where rethinking how we use what already exists is no longer optional, but necessary.

Q: What were some of the challenges or breakthroughs encountered in developing a glaze from reclaimed glass waste?

Consistency is a word that comes up often when working with waste in design, and it’s one of the biggest challenges we face with every new batch of material. Waste isn’t uniform by nature, so establishing clear communication with the supplier becomes essential.

Understanding how Sungai Watch collects, sorts, and cleans their recovered glass has been key. Equally important is being transparent about our own needs as end users of the material. Once that mutual understanding is in place, the potential of glass as a resource really begins to unfold.

One of our breakthroughs was eliminating a virgin raw material from our purchase order entirely, replacing it with a locally sourced waste alternative that is 23 times more cost-effective. From a single waste stream, we’ve developed multiple glazes with varying compositions, some containing up to 80 percent reclaimed glass.